Beginner’s Guide to Knife Making in South Africa - Tool Guide

The global interest in Knife Making has been ignited, thanks to popular TV programmes such as Forged in Fire as well as a plethora of YouTube channels.

In this Blog, we'll guide you through the basics of Knife Making in South Africa.

Broadly speaking, there's two categories of knife making: one approach is called stock removal, the other is forging.

Stock Removal

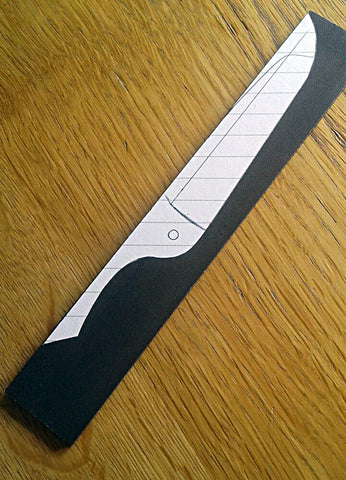

Stock removal knife makers use bar stock of appropriate hardenable steel – more about this in a minute. They mark out the design on the bar, then cut it out using either a band saw or angle grinder. The shape is refined using hand files, belt grinders or even a flap disc on an angle grinder. Bevels are ground or filed in and then a process of sanding removes all the scratches from the surface of the steel.

Finally, the steel is heated to critical temperature and quenched. This hardens the steel, but also makes it very brittle. The blade is then tempered to reduce brittleness while retaining much of the hardness. The change which takes place in steel is controlled by the final temperature to which the steel is heated, and the speed with which it is cooled. Some steels can be quenched in water, others require oil quenching. There are even some steels which harden simply in the air.

The final hardness is achieved through tempering, which requires heating the steel to a much lower temperature (typically around 200 degrees C) for a couple of hours. The blade is then allowed to cool slowly.

This process can be repeated several times to reduce pockets of stress that may remain. Some steels can benefit from cryogenic treatment right at the end of the tempering process. This entails placing the blade in a flask of liquid nitrogen for several of hours.

Forging

Bladesmiths, on the other hand, can start with bar stock or other irregular pieces of high carbon steel. These include motor vehicle leaf springs, coil springs from trucks, old files or even large industrial ball bearings.

The steel is heated in a forge to between 1100 and 1200 degrees C and then shaped on an anvil using a hammer. Some bladesmiths use power hammers and presses to speed up the process and reduce hand hammering.

Once the blade is roughly shaped, the process follows the same grinding, filing, sanding and finally the heat treating, quenching and tempering routine as stock removal knife makers.

What Steel to Use

Steel needs to contain between 0.4% and 2% carbon in order to be hardenable. When more than 13% chrome is added, it's described as stainless steel. Other elements that can be added include vanadium, manganese, nickel, molybdenum, nitrogen, titanium, cobalt, tungsten, silicon, copper and phosphorous.

These elements can affect the machinability of the steel, as well its corrosion resistance and performance at high temperatures. (A very useful resource is the free iOS App, Knife Steel Composition Database by ZviSoft)

Where to find knife making supplies in South Africa

Knife making tools and costs

At first glance, knife making appears to have some high barriers to entry. Most makers online use expensive belt grinders (in SA these range from around R15,000 to R25,000), blade smiths have gas forges for heating their steel and most have large anvils which can range in price from R2,000 upwards, depending on the size of the anvil and manufacturer.

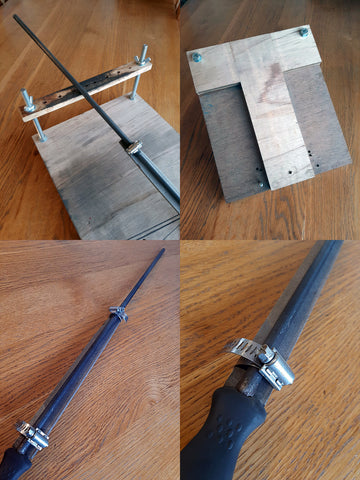

Despite this, it is perfectly possible to make a very respectable knife entirely with hand tools. A hacksaw and a range of hand files can do the work of the belt grinder and band saw. If you're attempting to file bevels into your knife, it would be a good idea to make a simple wooden jig to ensure you are maintaining a consistent angle.

Heat treating requires a forge or a heat treating oven. However, there are some steel suppliers who offer a heat treating service at a nominal cost. The benefit of industrial heat treatment is that vacuum ovens are used, reducing the amount of surface oxidation that takes place during this process.

The Handle

Once the blade has been sanded to a near final finish, the handle is added. This can be in the form of “scales” on full tang knives, or a block of handle material into which a partial or through tang is inserted.

Handle scales are made from a very diverse range of materials, including composites like micarta, G10, tufnol, parachord and wood. In South Africa we're spoilt for choice: we have access to leather, acrylic, bone and horn. Handles are generally glued on with epoxy and pinned for additional strength. It's possible to make a very effective micarta by layering pieces of fabric soaked in epoxy and then clamping it in a press. The handle's final shape is achieved through cutting and sanding.

All knife pics and jig courtesy of Pete van der Woude

Links to a selection of YouTube Channels

Where to find knife making supplies in South Africa

- Bohler Uddeholm (for N690 stainless, O1 and heat treatment) (021) 534-3551

- KMTS (general supplies including steel, knife blanks, machines, handle materials) www.KMTs.co.za

- Herbst Knife Making Equipment http://www.herbst.co.za/index.php/products-services/machines

- North West Knife Machine Manufacturers http://www.nwknives.co.za/

- Vormac (Belt Grinders) https://vormac.co.za/

- Gartech (suppliers of Tufnol and other industrial plastics) http://www.gartech.co.za/products.html#tufnol

Comments

Leave a comment